Additive Manufacturing System with Metals

Manufacturer & Model | |

| Machine | AconityLAB, Aconity3D |

| Scanning system | IntelliSCAN 30 and varioSCAN, SCANLAB |

Highlight | |

| Flexible change and extension of optics | |

| Flexible change and extension of monitorint | |

| Flexible control architecture | |

Key Features | |

| Build volume | Ø 170 x 170 mm |

| Laser | 1 kW Single Mode, SPI |

| Spot size | > 80 µm |

| Shielding gas | Argon and Nitrogen |

| Preheating | Platform heating of up to 1000 °C |

Technical DescriptionThe AconityLab is one of the first commercial systems from the manufacturer Aconity3D (a spin-off of the Fraunhofer ILT). The machine is equipped with a 1 kW single mode fiber laser and a pre-focused scanner system with a large 30 mm aperture, which enables small spot sizes (80 µm) and the flexible integration of different beam shaping concepts. The structural separation of the core machine and laser protection housing enables the uncomplicated integration of various monitoring systems. | |

Manufacturer & Model | |

| Machine | EOS M290, EOS |

| Laser | IPG YLR-2000-SM, IPG |

| Scanning system | Scanlab intelliSCAN Custom, Scanlab |

Highlight | |

| Customizable beam shaping through LCoS-SLM | |

| Off- & co-axial multispectral monitoring | |

| Reliable and mature, industrial AM system as foundation | |

Key Features | |

| Build volume | 250 x 250 x 325 mm |

| Laser | 1070 nm fibre laser, 2000W |

| Spot size | 80 – 1000 µm |

| Shielding gas | Argon and Nitrogen |

Technical DescriptionThe foundation for this research system is a state-of-the-art EOS M290 machine which has a highly modified optical setup to enable dynamic beam shaping. The optical setup is based on a Liquid Crystal on Silicon Spatial Light Modulator (LCOS-SLM) and enables the design and usage of arbitrary beam shapes. The maximum size of the usable beam shape is 1x1 mm. Additionally to the beam shaping technology, the machine is equipped with a cutting-edge monitoring system, consisting of two multispectral imaging cameras (MSI) which are mounted co-axial (through a port in the scanner) and off-axis (directly facing the powder bed). Thereby, the process can be monitored to allow for a better control and understanding of the observed effects (like overheating, keyholing, etc.). | |

Manufacturer & Model | |

| Machine | K2-2, Addimetal |

| Print Technology | Binder Jetting |

Highlight | |

| Open parameters ( adjustment of drop size) | |

| Modular technical compartments | |

| Network interframe | |

Key Features | |

| Build volume | 200 x 200 x 200 mm |

| Print head | up to 1080 DPI |

| Layer thickness | 40 – 1000 µm |

| Drying system | Adjustable IR flashlight |

| Liquid system | With recirculation |

Technical DescriptionThe Addimetal K2-2 is a metal binder jetting system designed for research applications in additive manufacturing. It features open parameter configurations, allowing for the investigation of printing strategies, deposition methods, and process optimization in industrial settings. Equipped with a high-resolution printhead, an adjustable drying system, and advanced powder handling mechanisms, the system enables precise control over each stage of the printing process. These capabilities support detailed experimentation and validation of binder jetting techniques for various applications. | |

Manufacturer & Model | |

| Laser | AFX-1000, nLIGHT |

| Scanning system | Raylase AM-Module, Raylase |

Highlight | |

| Beam shaping | |

| Beam zooming | |

| Co-axial monitoring | |

Key Features | |

| Build volume | 150 x 130 x 30 mm |

| Laser | 1070 nm fibre laser, 1200W |

| Spot size | 90 – 400 µm |

| Scan speed | up to 14.4 m/s |

| Shielding gas | Argon and Nitrogen |

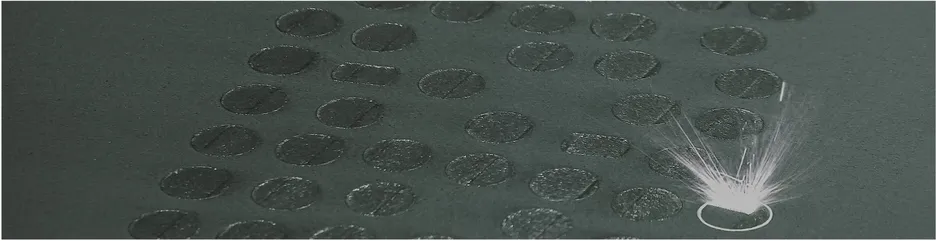

Technical DescriptionThe OptiBeam Pro is an in-house built PBF-LB/M system equipped with state-of-the-art functionality. It features the AFX-1000 laser, which offers seven switchable beam profiles ranging from Gaussian to Ring-shaped. The Raylase AM-Module scanning system provides beam zooming up to a factor of 2 and includes a co-axial monitoring system. Control of the system is managed by either a self-developed PLC or AMCF system. Various powders such as 316L stainless steel, Inconel 718 & 738, and Wolfram are utilized. This setup is dedicated to fundamental research, focusing on the impacts of beam shaping, co-axial absorption monitoring and keyhole detection, co-axial absolute temperature monitoring, and the exploration of novel materials. | |

Manufacturer & Model | |

| Laser | SPI single-mode laser with 400 W |

| Scanning system | Scanlab 3D scanning system |

Highlight | |

| Open software interface (AMCF) | |

| High-temperature build plate | |

| Variable monitoring possibility | |

Key Features | |

| Build volume | 250 x 250 x 300 mm |

| Laser | 1070 nm fibre laser, 400W |

| Spot size | 70 µm |

| Preheating | Platform preheating of up to 500 °C |

| Shielding gas | Argon and Nitrogen |

Technical DescriptionThe PHOENIX is a high-performance additive manufacturing system designed for precision and versatility in laser-based powder bed fusion of metals (PBF-LB/M) processes. The machine core, a Renishaw AM 400HT, is equipped with a 400 W fiber laser, which provides a stable beam quality and a 70 μm focus, ideal for high-quality metal part production. The system utilizes a galvanometer-based scanning system that ensures rapid and accurate beam delivery across the build platform, enabling the manufacturing of complex geometries and fine detail. The high-temperature module is capable of preheating the build plate up to 500 °C, making it an optimal fit for the stable processing of demanding alloys. On top of that, an open software package developed based on the Autodesk Machine Control Framework (AMCF) enables cutting-edge research. Scan path manipulation and innovative monitoring system integration are made possible by the full accessibility of the process chain from CAD to the final part. | |

Manufacturer & Model | |

| Machine | Truprint 1000, Trumpf |

| Laser | Fiber laser OEM 200W CW 6m |

| Scanning system | Scanner Miniscan II 14 1070 nm |

Highlight | |

| High-precision manufacturing | |

Key Features | |

| Build volume | Ø100 x 100 mm |

| Laser | 1070 nm fibre laser, 200W |

| Spot size | 55 µm |

| Scan speed | 6 m/s |

| Shielding gas | Argon and Nitrogen |

Technical DescriptionThe TruPrint 1000 by Trumpf is an industrial laser-based powder bed fusion machine with a small build volume. The 55 μm spot enables high-precision manufacturing of parts, allowing for the printing of complex geometries with high spatial resolution using 316L stainless steel. The industrial-standard machinery offers easy handling, making it suitable for both professional and educational use. | |