Buena – Cross-industry industrialization of additive production

The research project Buena aims to promote the cross-industry expansion of additive manufacturing (AM) for material- and energy-efficient lightweight construction. To this purpose, the consortium has identified five challenges of AM. As part of the project, various approaches to overcoming these barriers to industrialization are explored and elaborated. The focus is on powder bed fusion of metals using a laser beam (PBF-LB/M) and powder-based directed energy deposition (DED-LB/M).

Motivation

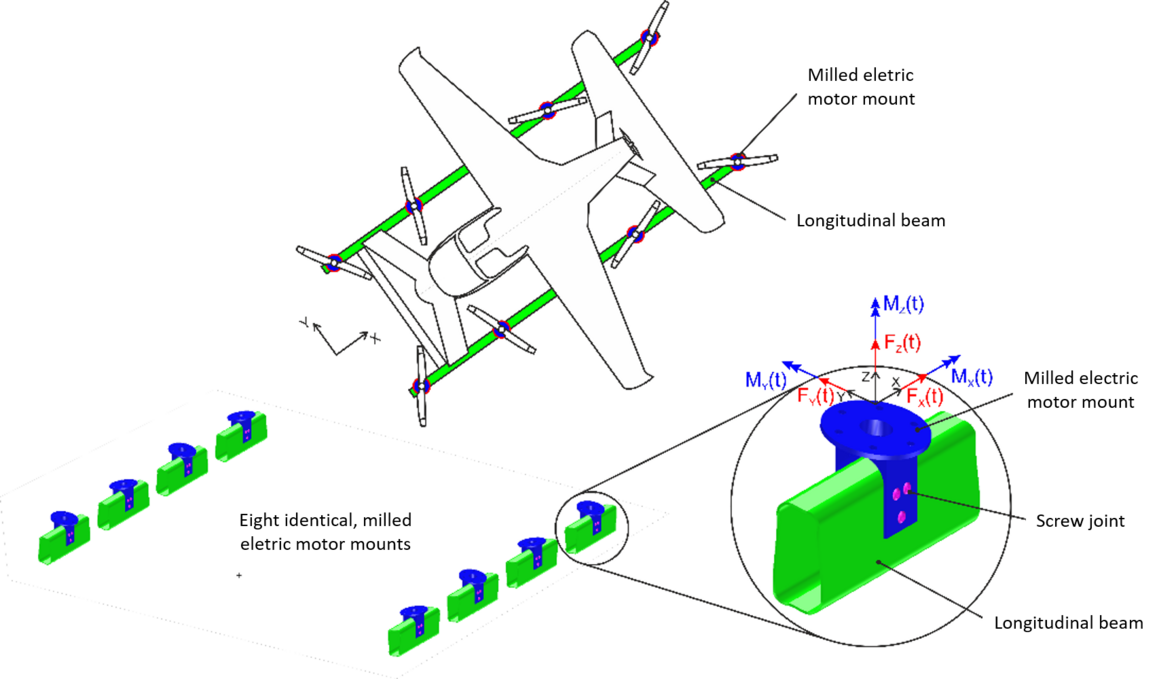

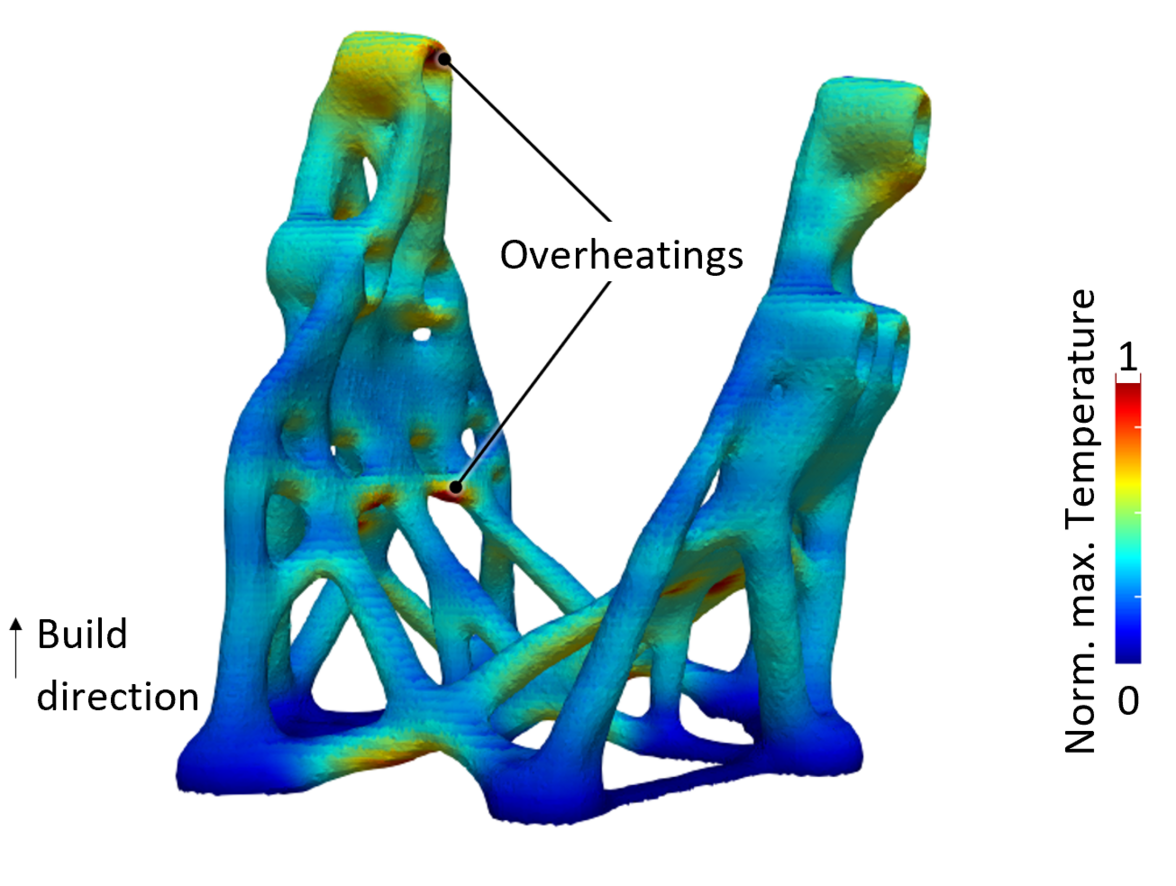

AM offers advantages, such as a functional integration, innovative design options, a customizability, and a considerable lightweight construction potential. These advantages result from the high degree of design freedom, which can only be achieved to a limited extent with traditional manufacturing processes. This design freedom enables a material-efficient topology optimization (TO), which generates load-path-optimized parts according to the bionic principle. Despite these benefits, AM has not yet become established in the industry to the expectations. One of the main reasons for this is the insufficient process stability during the manufacturing of topology-optimized components.

Objective

The overall aim of the research project is to promote material- and energy-efficient lightweight construction through AM. To this end, the build-up process is simulated at the iwb to detect overheatings in the parts. Subsequently, the critical areas in the part are identified from the simulation results. These areas are adapted in the topology optimization to increase the process stability in AM.

Approach

Until now, the design of additively manufactured parts has primarily been based on the requirements in terms of the functionality, the lightweight construction, and the mechanical properties. In the past, other important criteria, such as the process stability, the reworking and quality assurance costs, and the CO2 footprint, were often neglected. In the Buena project, a method is developed to optimize parts in a newly defined, complex target system.

At the iwb, the overheatings in the build-up process simulations are calculated using the software AscentAM, which was specifically developed for PBF-LB/M. In an iterative process, the critical areas of the parts are considered in the TO. In the further course of the project, the transferability to the DED process is tested. A GPU-based solver improves the efficiency of the computationally intensive thermal process simulation, and a straightforward graphical user interface simplifies the applicability.

Project partners

Bergische Universität Wuppertal: Lehrstuhl für Optimierung mechanischer Strukturen (BUW),

Boeing Deutschland GmbH (BOEING),

FIT AG (FIT),

Industrieanlagen-Betriebsgesellschaft GmbH (IABG),

Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e. V. Fraunhofer-Einrichtung für Additive Produktionstechnologien (IAPT),

nebumind GmbH (nebumind),

Technische Universität München: Lehrstuhl für Produktentwicklung und Leichtbau (LPL), and

J.M. Voith SE & Co. KG (VOITH)

Acknowledgements

The research project Buena is funded by Federal Ministry for Economic Affairs and Climate Action (BMWK) (project number: 03LB2046G). We would like to express our sincere thanks for this.