Department Machine Tools

The main task of the Department is the interdisciplinary development, construction and optimization of machine tools as well as the implementation of a suitable methodical approach. One focus is on the investigation and optimization of the dynamic behavior of machine structures. For this purpose, methods for simulation and experimental analysis of the structural behaviour, control and machining processes of machine tools are used. Furthermore, tools and procedures for the development of control software are developed. The control design of complex systems forms an important basis for the development and implementation of integrated adaptive structures and control methods to improve the dynamic machine properties.

Head of Department: Martina Elisabeth Sigl

Research Competences

- Digital twin for the machine tool

The research field focuses on the investigation and automation of the entire development process of digital twins for machine tools (machine twin and process twin). This starts with the systematic acquisition of data and ends with automated decision-making through the use of AI models.

Research Field Lead: Daniel Piendl

- Process behavior

The research field Process Behavior addresses current challenges in the machining of metallic materials. A particular focus is on hybrid process chains in which subsequent milling improves the component quality. Solutions are being developed for the machining post-processing of additively manufactured components (e.g., for remanufacturing purposes) as well as for the machining post-processing of components that are difficult to form.

Research Field Lead: Moritz Göldner

- Friction welding

The focus in this field of research is on the investigation of equipment technology – combined with artificial intelligence – for efficient quality monitoring during friction stir welding. Additionally, key areas include the employment of the process to weld innovative components driven by lightweight design as well as the adaptation of the friction stir process for entirely new application areas (e.g., liquid hydrogen tanks, battery production, rocket manufacturing).

Research Field Lead: Amanda Zens

Learn more on current projects here.

Equipment in the field of Machine Tools

5-axis universal mill-turn machining center GROB G352T

- Spindle speeds of up to 16,000 rpm, table size of 570 mm, max. table load of 350 kg, working area: 600 x 855 x 750 mm³

- Sensor technology: ToolScope system for tool monitoring, Spike-InSpindle system for recording axial forces and bending moments, tool camera for cutting images, Siemens-Edge device for recording machine data with a sampling rate of 0.5 kHz, OPC-UA interface

- Usage: 5-axis simultaneous milling of components

- Current research project (as of 2025): QuSAM, EREP, MINERVA, CICAM, MoVer

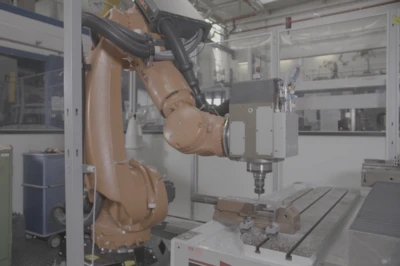

Industrial robot KUKA KR 24-R2500 prime

- Equipped with a milling spindle

- Spindle speeds up to 10,000 rpm; payloads up to 240 kg

- Sensor technology: Motion-Tracking system and Leica LT150 laser tracker

- Control/Regulation modes: Interface for external position control

- Usage: Milling and drilling of metals or plastics, development of methods for stiffness determination, offline compensation through cutting force models and information fusion for modeling dynamic behavior

- Current research project (as of 2025): ProKiRo

Grenzebach DSM 7-5

- Friction Stir Welding Spindle

- Travel speeds up to 20 m/min, plunge forces up to 8 kN, radial forces up to 2.6 kN, working area: 700 x 500 x 400 mm³

- Control platform: Bosch Rexroth ctrlX Core, OPC-UA interface

- Control/Regulation modes: Internal force control

- Usage: Joining of machine tool components

- Current research project (as of 2025): KIDZ

Miniature machine tool (self-built)

- Milling Spindle

- Replica of a DMG DMU 80 P

- Travel speeds up to 600 mm/min, working area: 70 x 70 x 35 mm³

- Operation: Raspberry Pi 4 Model B with touchscreen and "Universal G-Code Sender" software, control of the servomotors: Arduino Mega with Ramps 1.4 Board

- Usage: Demonstrations in courses/lectures and other demonstration purposes

KUKA KR 500-2 MT Heavy-Duty Industrial Robot

- Friction Stir Welding Spindle

- Speeds up to 2,500 rpm, plunge forces up to 10 kN

- Sensor technology: 3D profile sensor, internal force sensors, in-house developed temperature measuring device

- Control/Regulation modes: Internal force control and in-house temperature control

- Usage: Friction stir welding of 3D geometries

- Current research project (as of 2025): EffiHycient

Machining Center Gebr. Heller Maschinenfabrik MCH 250

- Friction Stir Welding Spindle

- Speeds up to 6,000 rpm, plunge forces up to 17.5 kN, table size up to 630 x 630 mm²

- Control system: Siemens Sinumerik 840D

- Control/Regulation modes: Position control, in-house force control, and in-house temperature control

- Sensor technology: Sensory tool holder SPIKE mobile (pro-micron), in-house developed dynamometer, in-house developed temperature measuring device, surface laser scanning system RobiScan (Automation W+R GmbH), optical recording system

- Usage: Friction stir welding, friction stir spot welding, micro friction stir spot welding

- Current research project (as of 2025): µKoBatt