Department Laser Technologies

Laser material processing enables the cost-effective manufacture of complex products and realizes innovations in the fields of electromobility and energy generation/storage, lightweight construction and surface functionalization. The Department Laser Technology is responsible for the investigation and further research of a representative range of laser-based joining and separation processes. The theoretical and experimental design of the processes, the integration of system technology as well as the implementation and realization of plant concepts form the center of these investigations. The work is accompanied by numerical simulation of the processes. In addition, modern concepts for process monitoring and data evaluation by means of AI are developed and used to support process optimization.

Head of Department: Fabian Vieltorf

The main research topics

Research Field: Laser Manufacturing Technology

The laser production technology at iwb deals with basic research on laser material processing and uses modern system technology for process monitoring. With the help of new approaches to data processing, the sensor signals of process monitoring are used to systematically achieve process improvements.

Research Field Leader: Pawel Garkusha

Research Field: Intelligent Joining System Technology

Intelligent joining system technology represents an interface between the individual research areas in the Laser Technology group. Here, methods for data acquisition and evaluation are adapted and further developed for use in production technology. Modern data processing methods ranging from statistics to machine learning are used to provide practical recommendations for industrial implementation.

Research Field Leader: Tony Weiß

Find out more about the current projects here.

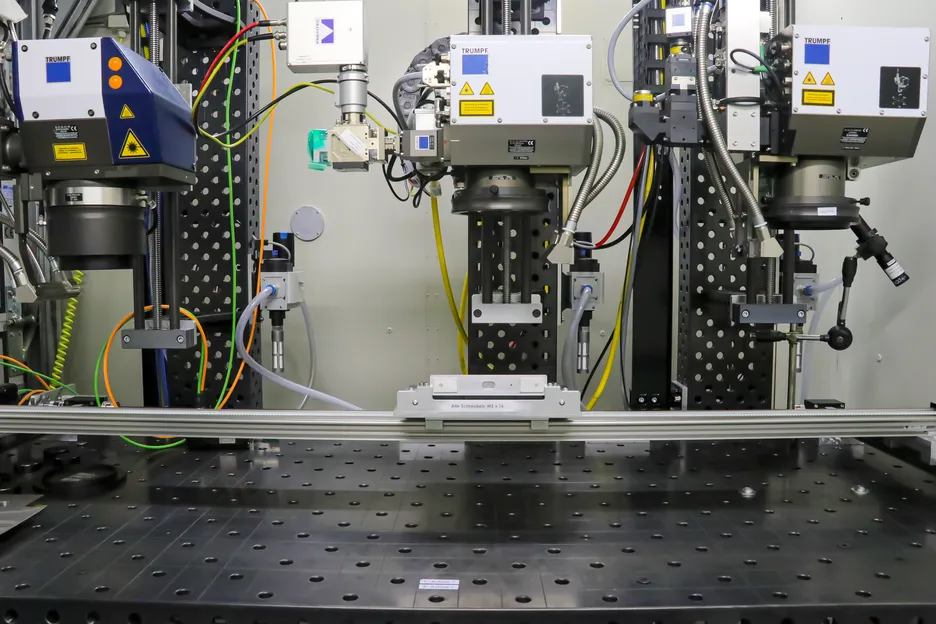

Equipment in the Department Laser Technologies

Laser Beam Sources

Multi-Mode Fiber Lasers (Infrared – IR)

- IPG, Maximum Power Pmax = 6 kW

- Coherent FL8000, Pmax = 8 kW

Single-Mode Fiber Lasers (IR)

- IPG YLR-3000 SM, Pmax = 3 kW

- TRUMPF TruFiber 1000, Pmax = 1 kW

Multi-Mode Disk Lasers

- TRUMPF TruDisk 4001, Pmax = 4 kW (IR)

- TRUMPF TruDisk 1020, Pmax = 1 kW (Green)

Ring-Mode Beam Sources

- Coherent HighLight FL 4000CSM-ARM, Pmax Core/Ring = 1.5/2.5 kW

- TRUMPF TruFiber 6000P, Pmax Core/Ring = 2/4 kW

Ultrashort and Short-Pulse Lasers

- IPG YLPP-25-3-50-R, 100 W, 30 ns, 0.2 mJ

- SPI redENERGY G4, 200 W, 10 ns, 5 mJ

- Innolas 1030-25-Yb-2500, 25 W, 500 fs, 25 µJ

- TRUMPF TruMicro 6020, 200 W, 850 fs, 200 µJ

Optics

State-of-the-art fixed optics, including options for tactile seam tracking and beam shaping, e.g.:

- HighYAG Bimo

- Scansonic ALO3

- Precitec YRC, and more

Various scanning optics for remote processing, e.g.:

- ScanLab IntelliWeld30

- TRUMPF PFO33

- Precitec ScanMaster

- Raylase AS-Fiber 30

- Scansonic RLW-A, and more

Accessories and Manipulators

- 6-axis articulated robots with various external kinematics

- Wire feeding devices

- Measurement systems for beam and power measurement

Sensor Systems for Process Monitoring

- OCT sensors (70 and 250 kHz)

- Photodiode sensors (50 and 250 kHz)

- High-speed cameras

- Multispectral camera

- Optical microphone

- Pyrometer

- Laser line scanner

Modeling and Simulation of Joining and Cutting Processes

- Adina

- COMSOL Multiphysics

- MSC Marc

- Sysweld

- Hypermesh

- Matlab