Research Topic

| Short Title | Bearing power losses |

| End of Project | 2023 |

| Funding | FVA-Nr. 364/VII Research Association for Drive Technology e.V., FVA |

| Contact | Division EHD-Tribocontact and Efficiency Division Calculation and Verification of Transmission Systems |

Project Description

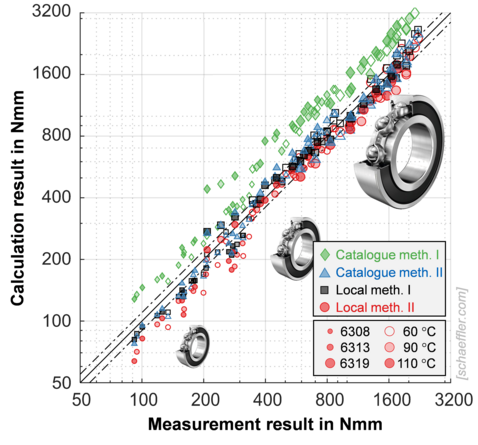

In gearboxes, rolling bearing power losses often make up a large amount of the total gearbox power losses. Therefore, an exact calculation of rolling bearing power losses is very important for resource and energy efficient gearbox design. The state of the art offers numerous friction calculation methods with different levels of detail to calculate power losses of rolling bearings. Bearing manufacturers like Schaeffler [Sch19] or SKF [SKF21] offer so called catalogue calculation methods, which are relatively simple and can be applied to standard rolling bearings. Contact-based/local methods like Schleich [Sch13] or “Low Friction Powertrain” (LFP) [Wan12] can consider a wider application field by generalization of tribological relations, which enables its application to e.g. hybrid bearings or non-standard bearings. The different methods may yield widely differing results. For its validation, measurement results are required. A systematic comparison of calculation results of different methods with measurement results was not available so far.

In this research project FVA no. 364/VII [Zan23], an analysis and evaluation of existing calculation methods and a broad comparison of calculation results with substantial measurement results were conducted. Based on the validation a classification of the calculation methods is derived, which provides guidance for the design engineer to choose the appropriate method for the respective application. Contact-based/local calculation methods have the potential to predict friction in rolling bearings precisely.

Literature

[Sch13] Schleich, T.: Temperatur- und Verlustleistungsverhalten von Wälzlagern in Getrieben, Dissertation, Technische Universität München (2013).

[Sch19] Schaeffler Technologies AG & Co. KG: Wälzlager - Technische Grundlagen und Produktdaten zur Gestaltung von Wälzlagerungen, Hauptkatalog (HR 1), Schweinfurt (2019).

[SKF21] SKF Gruppe: The SKF model for calculating the frictional moment, 17000-B5 (2021).

[Wan12] Wang, D.: Low Friction Powertrain - Teilprojekt G2.1 (Teil 2) - Wirkungsgradoptimiertes Getriebe, Abschlussbericht. Heft 1007/2, Forschungsvereinigung Verbrennungskraftmaschinen (FVV) e. V., Frankfurt am Main (2012).

[Zan23] Zander, M.: FVA 364 VII Lagerverlustleistungen - Studie zu Berechnungsmodellen zur Bestimmung der Lagerverlustleistung, Abschlussbericht. Heft 1547. Forschungsvereinigung Antriebstechnik (FVA) e. V., Frankfurt am Main (2023).