Experimentally validated advancement of calculation methods for the flank fracture load carrying capacity of bevel gears using AI-supported simulation and simplified calculation methods

Research Topic

| Short Title | Simulation and experiments on bevel gear flank fracture |

| Start of Project | Q2/2024 |

| Funding | FVA-Nr. 1028/I, IGF-Nr. 01IF23071N Federal Ministry for Economic Affairs and Climate Action, BMWK |

| Project Partner | Institute of Machine Elements and Machine Design (IMM), Technical University Dresden |

| Contact | M. Geitner, M.Sc. |

Project Description

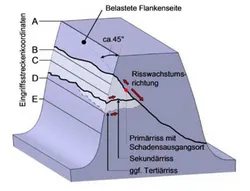

In recent years and decades, gears have been increasingly optimized with regard to scuffing, micropitting, tooth root breakage and pitting damage. Due to the calculation possibilities for safe design against these failure cases, gear damage due to flank breakage is increasingly occurring as a cause of gear failures. The calculation methods available to date do not allow a satisfactory prediction of the occurrence of flank fractures.

The aim of this research project is to make local, three-dimensional finite element methods for calculating stress and load carrying capacity for use in the design process available to SMEs for the first time. The load- carrying capacity, which is significantly influenced by the local hardness, can be determined by means of complex heat treatment simulations and is to be made representable in a computationally simplified manner using artificial intelligence (machine learning). The calculation methods of ISO/TS 6336-4 [ISO19] and FVA 556 III [Boi14] form the basis for this. The aim of the project is to develop a design concept for estimating the flank fracture risk of bevel gears that can be used in everyday engineering, both locally using suitable software and by applying simplified calculation method.

In order to develop a concept based on solid results, a comprehensive experimental and simulative investigation of tooth flank fracture damage is planned. The project is to be accompanied by tests at the FZG of the Technical University of Munich. The scientific and technical challenge lies in the computer-aided remodeling of the experimental investigations,which include metallographic investigations and topography measurements on the gear and test runs on the FZG bevel gear test rig. This project is intended to set a milestone in the systematic investigation of other materials, heat treatments and gear geometries with regard to their influence on flank fracture damage. This will make it possible in future to calculate a wide range of gear variations with regard to flank fracture.

Literature

[Boi14] Boiadjiev, I.: FVA 556 III - Heft 1100 - Nachrechnung Flankenbruch Kegelräder - Normfähiger Berechnungsansatz zum Flankenbruch bei Kegelrad- und Hypoidgetrieben, Forschungsvereinigung Antriebstechnik e.V., Frankfurt/Main (2014).

[ISO19] ISO/TS 6336-4:2019: Calculation of load capacity of spur and helical gears - Part 4: Calculation of tooth flank fracture load capacity.

[Wit12] Witzig, J.; Tobie, T. et. al: AVIF-Nr. 243, FVA 556 I - Heft 1000 - Flankentragfähigkeit-Werkstofftiefe - Entwicklung eines erweiterten Berechnungsverfahrens zur Ermittlung optimaler Zahnflankentragfähigkeit bis in den Bereich großer Werkstofftiefen, Forschungsvereinigung Antriebstechnik e.V., Frankfurt/Main (2012).