Computer-aided optimization of the efficiency and load-bearing capacity of worm gearboxes using free-form flank geometries

Research Topic

| Short Title | Freeform Design of Wormwheel-Flanks |

| Start of Project | Q1/2024 |

| Funding | FVA-Nr. 1024/I, IGF-Nr. 01IF23214N Federal Ministry for Economic Affairs and Climate Action, BMWK |

| Contact | M. Geitner, M.Sc. |

Projedt Description

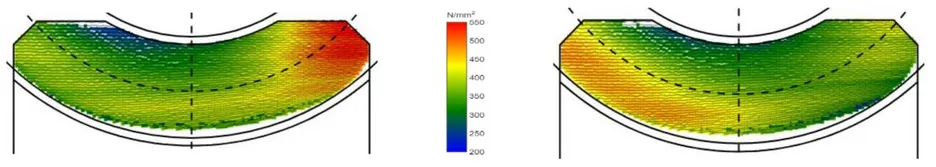

The project deals with the optimization of worm gears by means of the design possibilities using 5-axis milling technology. The main objectives of the optimization are to improve efficiency and power density. Optimized gear geometries are generated and evaluated using mathematical methods. The optimized worm gears are tested and evaluated experimentally by measuring the manufactured gears and carrying out tests on the component test rig. In the project, the geometry is first generated using the program SNETRA. Subsequently, the stresses and contact variables are adjusted by specific modifications of the flank topography which are then evaluated and optimized using a contact pattern simulation. The production strategy and parameters are programmed in a CAD-CAM environment. Based on this, worm wheels are manufactured for the experimental tests on a 5-axis machine. These are measured and examined in experimental tests for efficiency, running-in and scuffing load capacity. Reference tests with conventionally hobbed worm gears allow the properties of the modified 5-axis milled worm gears to be classified. This results in strategies for further optimization of the flank topography of worm gears and for the 5-axis production of these. Optimization options are developed and the potential for increasing efficiency and power density is assessed. The results can be taken up by gear manufacturers after the project and applied in development and production. Especially for smaller companies, the introduction and innovative application of alternative manufacturing technologies represents a proportionately large effort. The results can be used to prepare and support the introduction and application. The use of 5-axis technology therefore offers great potential for innovation and also the possibility of more flexible and economical small series and prototype production.