Research Topic

| Short Title | SIZA |

| Start of Project | Q1/2025 |

| Funding | DFG-Nr. 1198722-2 German Research Foundation, DFG |

| Website | Link zur Website des SPP2305 Website des SPP2305 in der GEPRIS-Datenbank der DFG Website des SIZA-Projekts in der GEPRIS-Datenbank der DFG |

| Project Partners | Institute of Automation and Information Systems, AIS, TU Munich Professorship for Smart Diagnostic and Online Monitoring, SDM, Leipzig University of Applied Sciences |

| Contact | Dr.-Ing. M. Otto |

Project Description

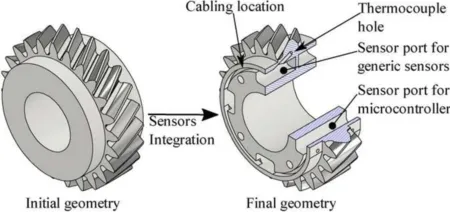

The potential damage to gears results directly or indirectly from the physical processes in the gear mesh. To ensure the most reliable condition monitoring possible, the aim was to record measurement data as close as possible to the gear mesh, with suitable sensors being integrated directly into the gear “in-situ”. Figure 1 shows the achieved package for the SIZA.

The aim is now to expand the existing prototypes and concepts to include additional features such as energy storage, energy harvesting and wireless data transmission. In addition to extending the functionality, the service life is also being tested under typical operating conditions in order to ensure the reliability and performance of the electronic systems and the modified gear wheel body.

To this end, cooperation is also planned within the priority program, which will promote the standardization of sensor-integrated machine elements with regard to standards and guidelines Also, the goal of networking between several sensor-integrated machine elements is the aim of achieving better monitoring of machine systems through diverse distributed sensor technology.

Literature

[Bon22] Bonaiti, L.; Knoll, E.; Otto, M.; Gorla, C.; Stahl, K.: The Effect of Sensor Integration on the Load Carrying Capacity of Gears. Machines 10. Heft: 10, S. 1–4 (2022).

[Fro19] Fromberger, M.; Sendlbeck, S.; Rothemund, M.; Götz, J.; Otto, M.; Stahl, K.: Comparing Data Sources for Condition Monitoring Suitability. Forschung im Ingenieurwesen 83. Heft: 3, S. 521–527 (2019).

[Kir24] Kirchner, E.; Wallmersperger, T.; Gwosch, T.; Menning, J. D. M.; Peters, J.; Breimann, R.; Kraus, B.; Welzbacher, P.; Küchenhof, J.; Krause, D.; Knoll, E.; Otto, M.; Muhammedi, B.; Seltmann, S.; Hasse, A.; Schäfer, G.; Lohrengel, A.; Thielen, S.; Stiemcke, Y.; Koch, O.; Ewert, A.; Rosenlöcher, T.; Schlecht, B.; Prokopchuk, A.; Henke, E.-F. M.; Herbst, F.; Matthiesen, S.; Riehl, D.; Keil, F.; Hofmann, K.; Pape, F.; Konopka, D.; Poll, G.; Steppeler, T.; Ottermann, R.; Dencker, F.; Wurz, M. C.; Puchtler, S.; Baszenski, T.; Winnertz, M.; Jacobs, G.; Lehmann, B.; Stahl, K.: A Review on Sensor‐Integrating Machine Elements. Advanced Sensor Research (2024).

[Kno23] Knoll, E.; Rupprecht, B.; Groppo, E.; Otto, M.; Vogel-Heuser, B.; Brederlow, R.; Stahl, K.: MODULAR EXTENSION OF FZG-GEAR TEST RIG FOR IN-SITU MEASUREMENT POSSIBILITIES. 29th International Congress on Sound and Vibration, Prag. IIAV CZECH s.r.o. (2023).

[Kno24] Knoll, E.; Rothemund, M.; Otto, M.; Rupprecht, B.; Ochs, M.; Vogel-Heuser, B.; Brederlow, R.; Stahl, K.: Evaluation of vibration behavior at different sensing positions on gearboxes. Forschung im Ingenieurwesen 88. Heft: 1 (2024).

[Küc24] Küchenhof, J.; Breimann, R.; Kirchner, E.; Gomberg, I.; Trieu, H. K.; Alamsha, K.; Knoll, E.; Stahl, K.; Menning, J.; Wallmersperger, T.; Ewert, A.; Schlecht, B.; Prokopchuk, A.; Henke, E.-F. M.; Seltmann, S.; Hasse, A.; Chen, C.; Drossel, W.- G.; Krause, D.: Development of a model-based modular building kit for sensorintegrating machine elements—Theory and application. Forschung im Ingenieurwesen 88. Heft: 1 (2024).

[Rup23] Rupprecht, B.; Sendlbeck, S.; Vogel-Heuser, B.; Brederlow, R.; Knoll, E.; Stahl, K.: Analysis of Acceleration Data using Low-Power Embedded Devices to Detect Gear Faults. 19th International Conference on Automation Science and Engineering, Auckland. IEEE (2023).

[Rup24] Rupprecht, B.; Vogel-Heuser, B.; Hujo, D.; Vicaria, A.; Knoll, E.; Stahl, K.; Ochs, M.; Brederlow, R.: A Microcontroller Operating Strategy for (Micro-)Pitting and Temperature Increase Detection in Sensor-Integrating Gears Evaluated With Prerecorded Sensor Data. International Conference on Industrial Engineering and Engineering Management 2024 (IEEM24), Bangkok (2024).